GOOD BOURBON

IS MADE IN DUE TIME.

AND IN DUES PAID.

As the First Family of Bourbon, we’ve been at work on our craft for centuries. Sometimes we break the rules, but there’s one we always follow: only bottle whiskey worthy of the Beam name. Here’s a few ways we do that.

01

CRAFTED BY THE CLIMATE AND CROPS OF KENTUCKY.

Cold, harsh winters and scorching hot summers keep southern living interesting to say the least - but they also create the perfect climate for aging whiskey. Our bourbon owes a lot of its rich flavor to the wide-ranging, four-season climate here in Kentucky. Additionally, corn thrives in the Bluegrass State – which is ideal since this is the key ingredient we use for mashing and distilling.

02

KENTUCKY WATER.

FILTERED THROUGH GENERATIONS.

Kentucky is located on a natural limestone shelf that acts as a filter, creating iron-free, calcium-rich water. This contributes to the flavor and appearance of the bourbon and its high pH also assists with fermentation. To preserve our whiskey’s most valuable asset, we’ve partnered with the Bernheim Arboretum and Research Forest to establish a water sanctuary that surrounds and protects our water source for generations to come.

03

A YEAST KNOWN AROUND THE WORLD.

Without it, we wouldn’t be what we are today. Because this isn’t just any old yeast. It’s a very specific old yeast – the same strain our family has been using since the end of Prohibition in 1933. It’s such a closely guarded secret, that Jim Beam himself would take a jug of yeast home for safe keeping every weekend.

04

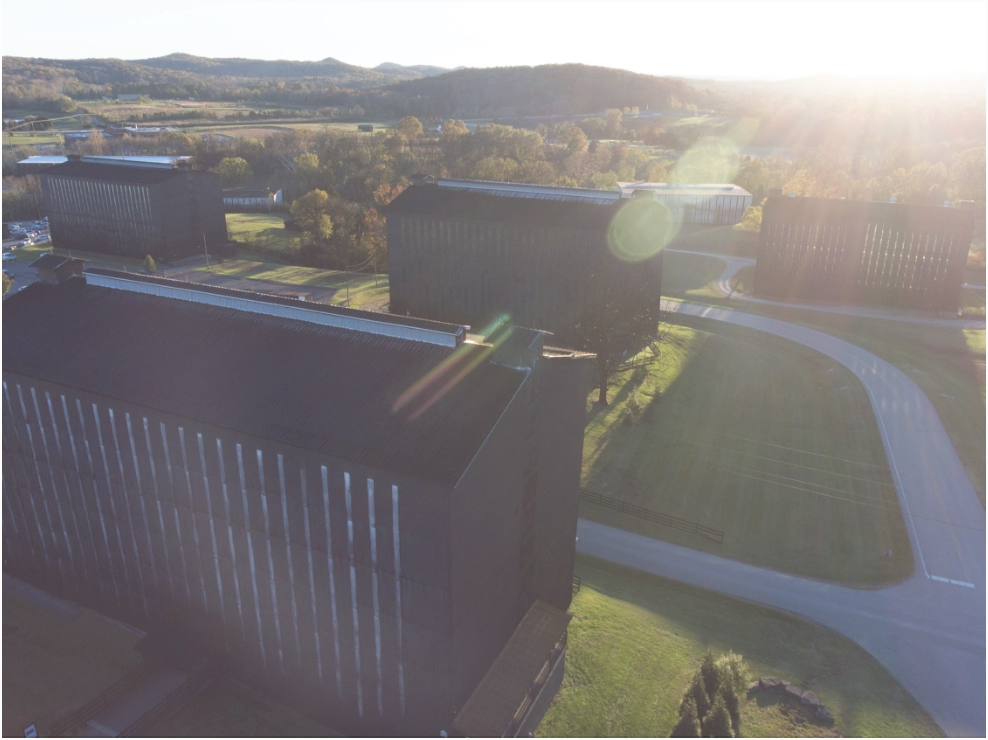

THE DIFFERENCE IS IN THE DISTILLATION.

Jacob carried our first still to Kentucky on his back. And for 8 generations, we’ve been hard at work perfecting our distillation process. Today we use our proprietary mash bills, our 65 ft. legacy still, and adjust distillation and entry proofs throughout the process. Our “Hardest Working Still in America” helps to craft a range of distinct whiskeys at the James B. Beam distilling Co.

You must be of legal drinking age to enter.

Beam Distilling encourages responsible drinking. Alcohol should be consumed in moderation. By entering this website, you are agreeing to our Terms and Conditions, Privacy Policy and Cookie Policy.